Categories Tuning Forks Informations about the Cosmic Octave and the Tu...

Informations about the Cosmic Octave and the Tuning Forks

The Cosmic Octave

With the octave formula f . 2n (= multiple doubling of a frequency) the Swiss mathematician and music researcher Hans Cousto calculated in 1978 from the orbital and rotational frequencies of the earth, the moon and the planets the corresponding sound frequencies. For this formula the term Cosmic Octave has become common..

For detailed information about the Cosmic Octave and the different planetary tone frequencies please see

www.planetware.de/octave/cosmic-octave.html

Striking the tuning fork

Striking the tuning fork

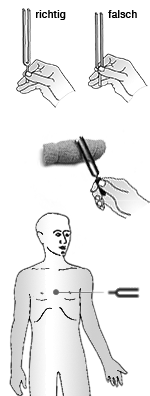

To strike the tuning fork, hold the shaft of the tuning fork with thumb, index and middle finger and strike the end of one fork arm against an object with a little momentum from the wrist. The fingers should not touch the bulge where both fork arms merge into the stem of the tuning fork, so that the fork arms vibrate freely and longer.

The tuning fork should not be struck on hard objects, otherwise an undesirable high overtone - a soft whistling tone - will emerge. Even with special, commercially available tuning fork stop blocks made of hard rubber, this high overtone was still audible in tests.

If the tuning fork is rarely used, it can be struck on the ball of the other hand. If the tuning fork is used frequently, an object that is approximately as soft as the ball of your hand can be used to strike the tuning fork. A tightly rolled up guest towel is well suited, the roller lashed at both ends with two cords.

If two Velcro straps are sewn to the towel (instead of the two strings), this towel can be used to transport the tuning forks and wrap them in it.

Tuning fork sonopuncture

The vibration of the tuning fork can be used to 'massage' points on the body with a specific vibration frequency. For the so-called sonopuncture, also called sonopuncture or phonophoresis, the stem of the tinting and vibrating tuning fork is placed on the body for a while and when the vibration has subsided, the tuning fork is struck again and placed again for minutes and this is repeated several times.

The ergonomic grip pad of the tuning fork models Splus and Lplus allows a more relaxed permanent use. The shape and material of this grip pad allows the tuning fork to be held more loosely, which means that the fingers holding it do not tire as quickly.

Tuning fork material

The tuning forks are made of high-quality steel; for the S and Plus models it is so-called gong steel and for the L and Lplus models it is a special tool steel. To prevent the steel from rusting, the tuning forks are nickel-plated. The main reason why stainless steel is not used is that it is tougher, so the tuning fork would have a much shorter oscillation period.

About a possible nickel allergy

The tuning forks offered at Planetware are made of nickel-plated steel. Since Planetware was founded in 1990, no problems have been reported because of the material; not even regarding a nickel allergy. Reactions to nickel in allergy sufferers usually only occur with prolonged contact with the skin, e.g. when wearing earrings, while in tuning fork applications the contact is relatively short. But certainly someone can be more or less allergic to nickel.

Our models Splus and Lplus have a grip pad, so there is no contact with the skin when holding the tuning fork. If there is fabric between the person's skin and the tuning fork, no allergy can be caused either.

Frequency accuracy (Steel vs. aluminum)

Whether tuning music or in sonopuncture, frequency accuracy is crucial for the highest possible resonance. Accordingly, the tuning forks offered here are manufactured with the highest precision. Compared to aluminum, steel tuning forks have a much more stable frequency accuracy when exposed to temperature fluctuations. This is especially important when using sonopuncture, because the tuning fork is held in the hand for a longer period of time and thus heats up. Steel hardly changes due to body heat, while aluminum expands more and thus the frequency becomes somewhat lower.

> Back to the tuning fork selection